3D ABL ADJUSTABLE BEAM LASERS

SPECIFICATIONS

Nominal Power (W)

Power Range (%)

Laser Beam Quality

Power Stability (%)

Pulse Frequency Range (kHz)

Wavelength (nm)

Voltage (VAC)

Cooling Capacity (kW)

Flow Rate Laser (l/min)

Temperature Laser (°C)

Fiber Interface

Diameter (μm)

Length (m)

Power Range (%)

Laser Beam Quality

Power Stability (%)

Pulse Frequency Range (kHz)

Wavelength (nm)

Voltage (VAC)

Cooling Capacity (kW)

Flow Rate Laser (l/min)

Temperature Laser (°C)

Fiber Interface

Diameter (μm)

Length (m)

ABL 1500/1500

1500W/1500W

1-100

Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

50/150 / 50/300 / 100/300

10-20

1-100

Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

50/150 / 50/300 / 100/300

10-20

ABL 2000/2000

2000W/2000W

1-100

Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

50/150 / 50/300 / 100/300

10-20

1-100

Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

50/150 / 50/300 / 100/300

10-20

ABL 4000/2000

4000W/2000W

1-100

Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

9

75

0-45°C

QBH, QD, Q+

50/150 / 50/300 / 100/300

10-20

1-100

Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

9

75

0-45°C

QBH, QD, Q+

50/150 / 50/300 / 100/300

10-20

ABL 2000/4000

2000W/4000W

1-100

Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

9

75

0-45°C

QBH, QD, Q+

50/150 / 50/300 / 100/300

10-20

1-100

Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

9

75

0-45°C

QBH, QD, Q+

50/150 / 50/300 / 100/300

10-20

ABL 4000/4000

4000W/4000W

1-100

Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

12

100

0-45°C

QBH, QD, Q+

50/150 / 50/300 / 100/300

10-20

1-100

Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

12

100

0-45°C

QBH, QD, Q+

50/150 / 50/300 / 100/300

10-20

3D ABL-SM ADJUSTABLE BEAM LASERS

SPECIFICATIONS

Nominal Power (W)

Power Range (%)

Laser Beam Quality

Power Stability (%)

Pulse Frequency Range (kHz)

Wavelength (nm)

Voltage (VAC)

Cooling Capacity (kW)

Flow Rate Laser (l/min)

Temperature Laser (°C)

Fiber Interface

Diameter (μm)

Length (m)

Power Range (%)

Laser Beam Quality

Power Stability (%)

Pulse Frequency Range (kHz)

Wavelength (nm)

Voltage (VAC)

Cooling Capacity (kW)

Flow Rate Laser (l/min)

Temperature Laser (°C)

Fiber Interface

Diameter (μm)

Length (m)

ABL-SM 1000/1000

1000W/1000W

1-100

Single/Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

14/110 / 20/110 / 14/150

10-20

1-100

Single/Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

14/110 / 20/110 / 14/150

10-20

ABL-SM 1500/1500

1500W/1500W

1-100

Single/Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

14/110 / 20/110 / 14/150

10-20

1-100

Single/Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

14/110 / 20/110 / 14/150

10-20

ABL-SM 1500/3000

1500W/3000W

1-100

Single/Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

14/110 / 20/110 / 14/150

10-20

1-100

Single/Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

14/110 / 20/110 / 14/150

10-20

ABL-SM 1500/4500

1500W/4500W

1-100

Single/Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

14/110 / 20/110 / 14/150

10-20

1-100

Single/Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

14/110 / 20/110 / 14/150

10-20

ABL-SM 2000/4000

2000W/4000W

1-100

Single/Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

14/110 / 20/110 / 14/150

10-20

1-100

Single/Multimode

∓2%

50

1070∓5nm

380VAC/ 50Hz/60Hz

6

50

0-45°C

QBH, QD, Q+

14/110 / 20/110 / 14/150

10-20

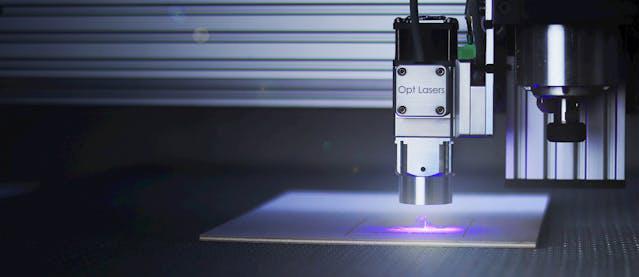

The Importance of ABL Lasers in Industrial Applications

Cost Savings

Reduced Rework

Faster Production

Enhanced Welding Quality

Industry 4.0

Maintenance and Repair

Body Manufacturing

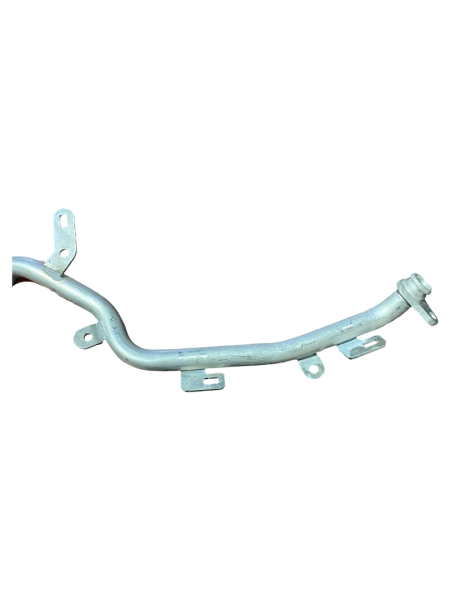

Engine and Transmission Components

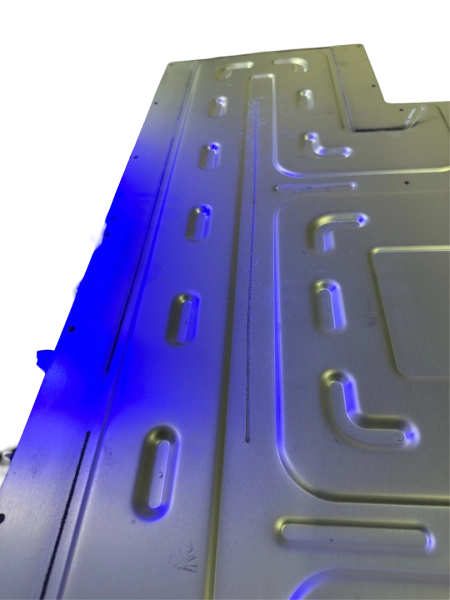

Battery Production

Industrial Applications with ABL Technology

Battery Welding

In Li-ion battery production, laser welding is used in delicate processes such as joining electrode layers and cell assembly. Laser welding improves the structural integrity and performance of the battery by offering a high level of control and automation. This technology increases the speed and efficiency of production processes while maximizing battery safety.

Defense Industry

Adjustable Beam Lasers have been developed for use in defense industry applications. One example is their use in surface hardening and precise hole drilling processes in the defense industry.

3D Printing

Adjustable Beam Lasers can be used to create complex 3D models and prototypes through a process called laser sintering, where the laser melts and fuses fine powder particles to form a solid object.

Automotive

Adjustable Beam Lasers offer convenience and speed in deep penetration and welding of different metals in the automotive industry.

Battery Cooling Systems

Adjustable Beam Lasers used in welding applications reduce the risk of errors and increase efficiency by providing high precision and fast welding processes. They also minimize the formation of weld spatter and can tolerate larger gaps compared to traditional laser welding.

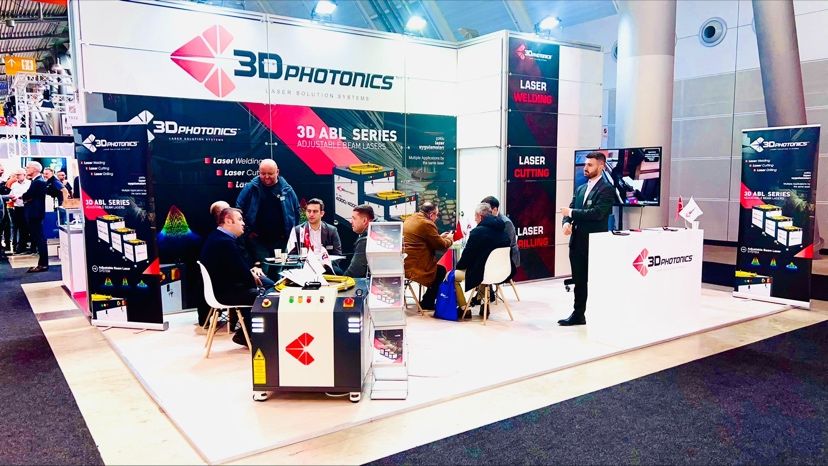

WHY 3D PHOTONICS?

3D Photonics is a leading technology company that provides fiber laser resonators and laser heads to numerous customers worldwide. The company has a broad customer base in Europe, Asia, and America, and continues to add value to industries in these regions.

In 2015, 3D Robotik started its activities by recognizing the potential of fiber laser technology. From the moment of its establishment, the company was determined to work on robotic fiber laser applications, fiber laser resonator, and laser head development. Over the years, through research and development efforts, the company consistently increased its knowledge in this field, ultimately leading to the formation of 3D Photonics.

3D Photonics holds a leading position worldwide by providing its customers with high-quality products and technical support, contributing to the proliferation of fiber laser technology. With a commitment to delivering value to its customers, the company continues to contribute to the success of industries in Europe, Asia, and America.

ABOUT US

MEDIA