Additive Manifacturing

Additive Manufacturing: The Future of Production

With the rise of Industry 4.0, manufacturing processes are being redefined around speed, flexibility, and customized solutions. Additive Manufacturing (AM), commonly known as 3D printing, stands at the core of this transformation. From metals to polymers, ceramics to composite materials, additive manufacturing is revolutionizing the way industries approach both prototyping and mass production.

What is Additive Manufacturing?

Additive manufacturing is a production method where material is deposited layer by layer to create a three-dimensional product. Unlike traditional manufacturing methods that rely on subtracting material (cutting, milling, machining), additive manufacturing uses material only where needed. This not only reduces waste but also enables the realization of highly complex and innovative designs.

Key Advantages of Additive Manufacturing

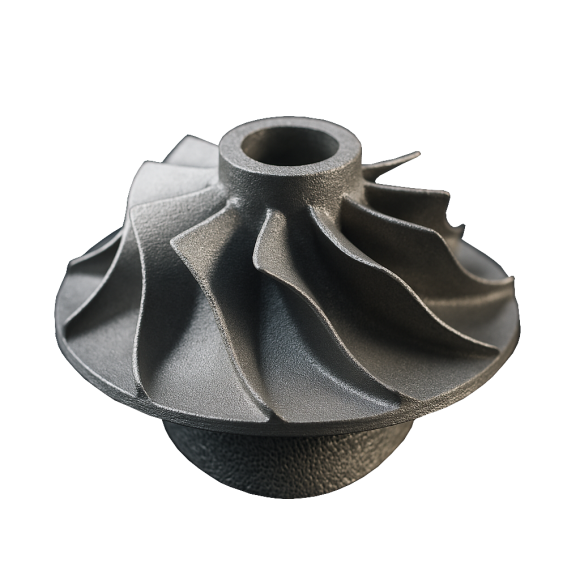

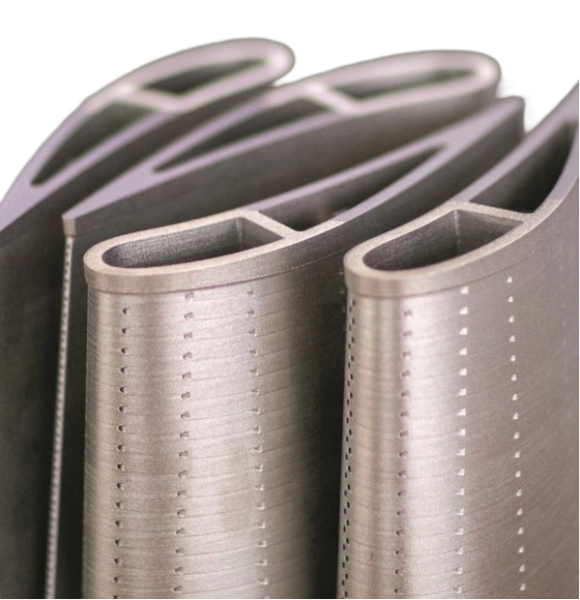

- Design Freedom: Complex geometries, internal channels, organic structures, and lightweight designs can be manufactured without the limitations of conventional methods.

- Rapid Prototyping: Cuts development time from days to hours, accelerating R&D and innovation cycles.

- Material Efficiency: Since material is only added where required, waste is minimized, leading to significant cost savings.

- Customization: Ideal for producing patient-specific medical implants, tailored tools, and low-volume production with cost efficiency.

- Integration with Robotics and Laser Systems: When combined with robotics and advanced laser technologies, AM becomes scalable for industrial mass production with unmatched precision.

Applications of Additive Manufacturing Across Industries

1. Automotive and Aerospace

Lightweight structures, fuel efficiency, and durability are critical in these sectors. Additive manufacturing enables the production of high-strength alloy parts, engine components, turbine blades, and structural elements with reduced weight and increased performance.

2. Medical and Healthcare

Custom prosthetics, implants, and surgical tools can be designed and produced with exceptional precision. Patient-specific solutions not only shorten production time but also improve treatment success rates.

3. Energy and Industrial Manufacturing

From high-temperature turbine components to quick spare part production, AM delivers reliable solutions in the energy and industrial sectors. Heat exchangers, pumps, and repair parts can be manufactured on-demand, reducing downtime and costs.

4. Consumer Goods and Home Appliances

Functional prototypes help test product design aesthetics quickly, while low-volume personalized production becomes economically feasible. In the home appliance industry, AM shortens time-to-market for innovative new designs.

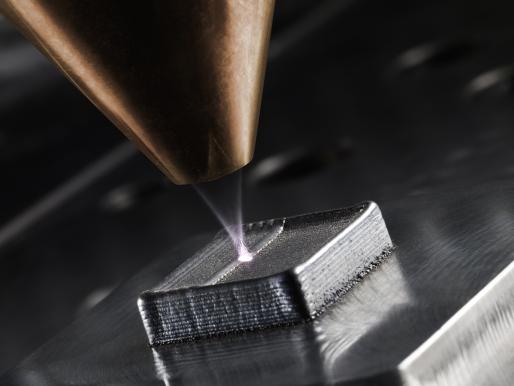

The Power of Additive Manufacturing with Laser Technologies

At 3D Photonics, we integrate additive manufacturing with advanced laser systems. Laser-based additive manufacturing methods such as Laser Powder Bed Fusion and Directed Energy Deposition enable the direct production of high-precision metal parts from powder or wire feedstock. This results in:

- Manufacturing of complex geometries in a single step,

- Enhanced mechanical strength of components,

- High-speed processes optimized for serial production.

Take Your Manufacturing into the Future

Whether you are producing lightweight components for aerospace, patient-specific solutions for healthcare, or high-precision parts for automotive, 3D Photonics Additive Manufacturing Solutions are ready to transform your production processes.

To learn more, see our technologies in action, or request a demo, get in touch with us today. Bring the future of manufacturing into your business with the power of additive manufacturing.